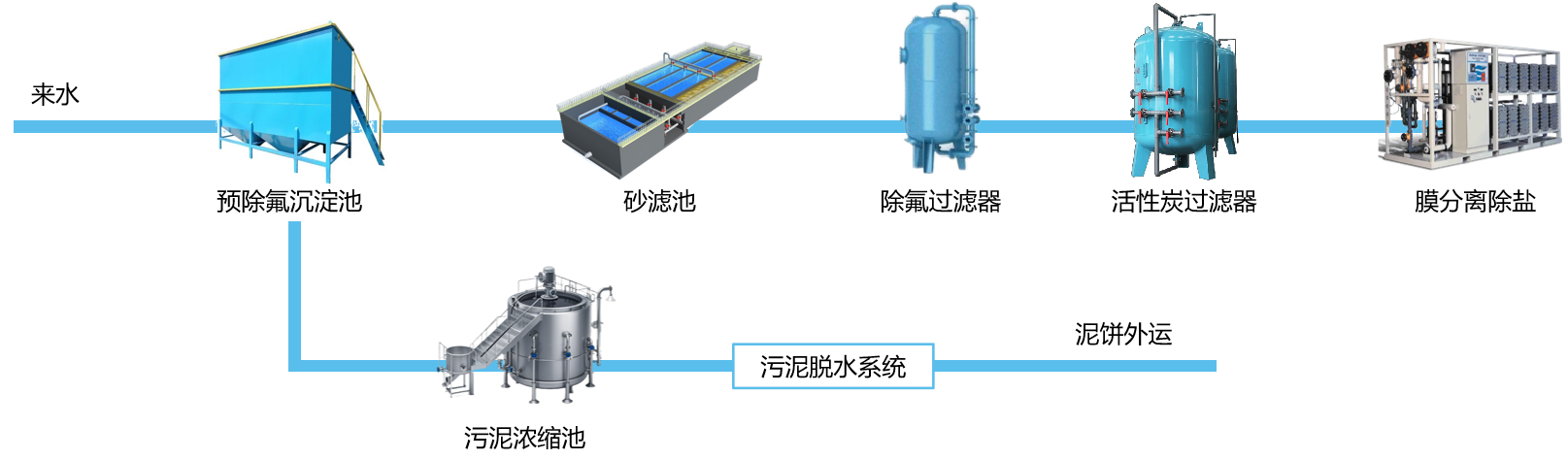

Process Flow Diagram

Technical Reserve

Develop a fluoride removal technology system of "coagulation sedimentation - modified adsorption - intelligent regeneration" to break through the pH limitations of traditional processes and the bottleneck of adsorbent consumption, achieving economical and efficient treatment.

1、Modified Adsorption Materials: Activated alumina applicable at pH 5-8, with an F⁻ adsorption capacity of 6 mg/g. Single column operates for 72 hours, with effluent ≤1.5 mg/L.

2、Fluidized Bed Crystallization Process: Introducing seed crystals to promote calcium fluoride crystallization, reducing sludge production by 30% and enhancing fluoride ion removal rate to 90%.

3、Intelligent Regeneration System: Automatically identifies penetration points, reduces acid-base consumption by 40%, achieves 95% fluoride recovery from regeneration solution, and minimizes losses.

Industrialization Advantages

Create an integrated fluoride removal equipment solution featuring cost-effectiveness and rapid deployment capabilities to facilitate precise remediation of fluoride contamination in mines.

1、Lightweight Design: Integrated adsorption-regeneration module enables 20-day installation, occupying only 60% of traditional footprint, adaptable to compact mountainous layouts.

2、Full-process Cost Advantage: Self-producing adsorbents reduces material costs by 35%, with comprehensive operation cost ≤0.8 CNY/m³.

3、IoT Monitoring Service: Real-time tracking of adsorption parameters, automatic breakthrough warning, and regular activation to ensure long-term compliance.

Related products