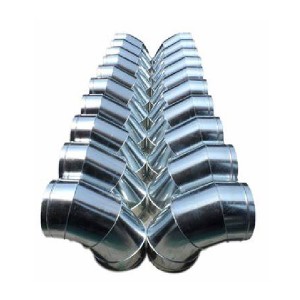

Custom Tee

A custom tee consists of main pipe interfaces, branch ports, and connecting components, made of stainless steel/PP/PVDF as per working conditions. It can be customized for reducing sizes (e.g., DN100×DN80), non-standard angles (30°-120°), and special connections (welding/flanged/threaded). Featuring corrosion resistance (to strong acid/alkali media), high-pressure adaptability (PN16-PN40), and optimized flow channels (local resistance coefficient ≤0.3), the inner wall is electropolished (roughness Ra≤1.6μm). Fluid dynamics simulation optimizes branch layout to ensure uniform flow division (deviation ≤±3%). Applied in chemical non-standard pipeline splitting, water treatment special water distribution systems, new energy equipment fluid allocation, and customized piping connections in automated production lines, customizable per ASME B16.9 or specific client requirements.