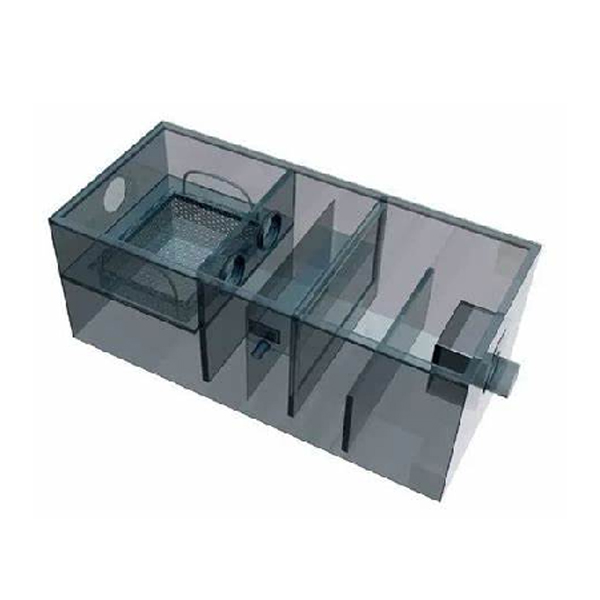

Oil Separator

The oil separator consists of an inlet water distribution device, inclined plate separation zone (with coalescing packing), oil collection tank (with automatic oil scraper), effluent weir, and sludge discharge system. With a treatment capacity of 10-1,000m³/d and oil removal efficiency ≥95%, it separates oil droplets ≥50μm in size, featuring short retention time (1-2h), high oil recovery rate (>90%), and intelligent operation (level-controlled oil scraping). Leveraging the density difference between oil and water (ρoil<ρwater), oily wastewater passes through the inclined plate zone where oil droplets coalesce and float to the collection tank, while clean water discharges through the weir and sludge settles for periodic removal. Widely used in oil-containing wastewater treatment for mining machinery maintenance (e.g., underground equipment flushing water), municipal catering oil pollution control, food processing plant grease separation, and petrochemical industry oily wastewater pretreatment, suitable for purification of industrial and domestic sewage containing vegetable/animal oils or mineral oils.