1、Long-term Anti-fouling Membrane Technology: Nano-coated RO membranes (primary/secondary) extend chemical cleaning cycles to 6-12 months with salt rejection efficiency ≥99%.

2、Dynamic Water Quality Optimization Algorithm: AI performs real-time analysis of ionic residues (including trace ions post-EDI) and particulate concentration, achieving a membrane fouling early warning rate ≥90%.

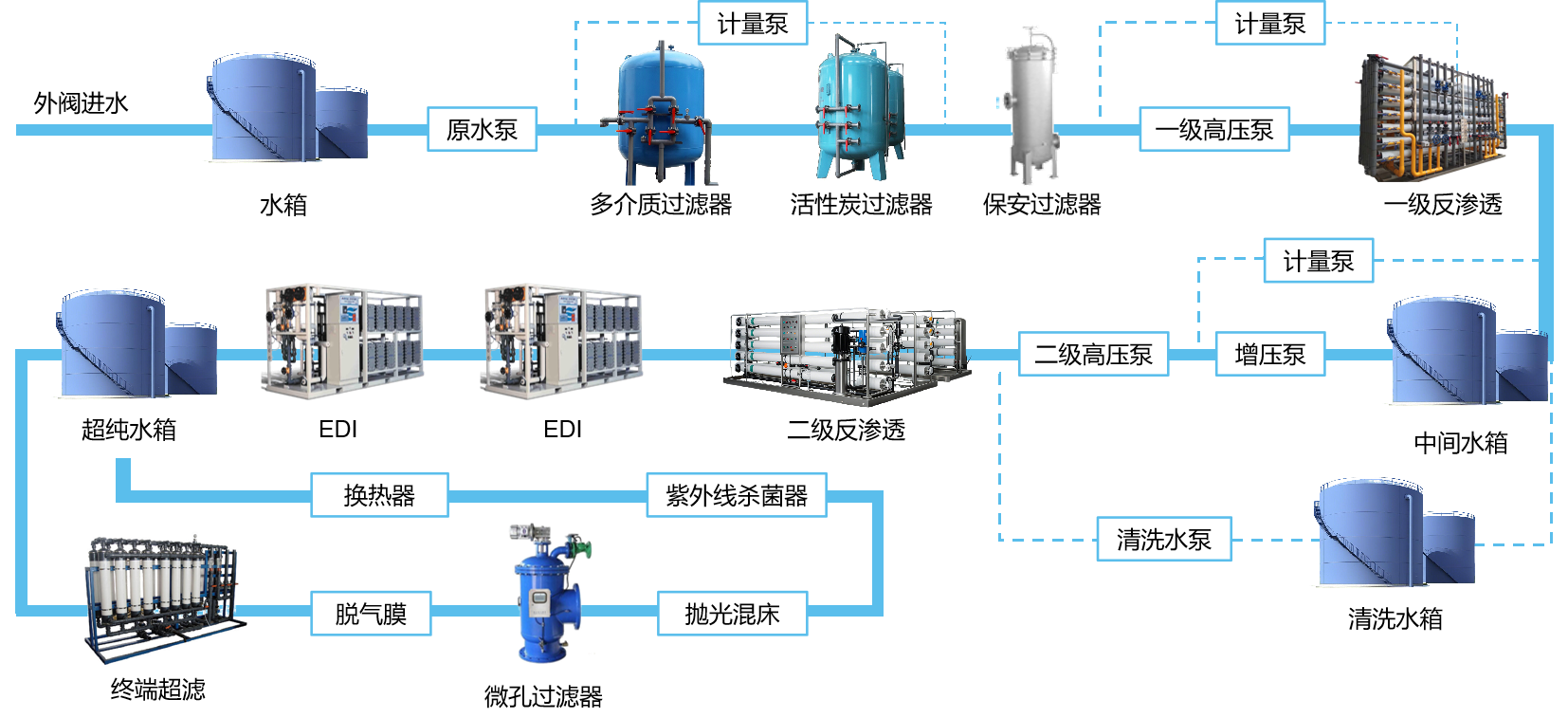

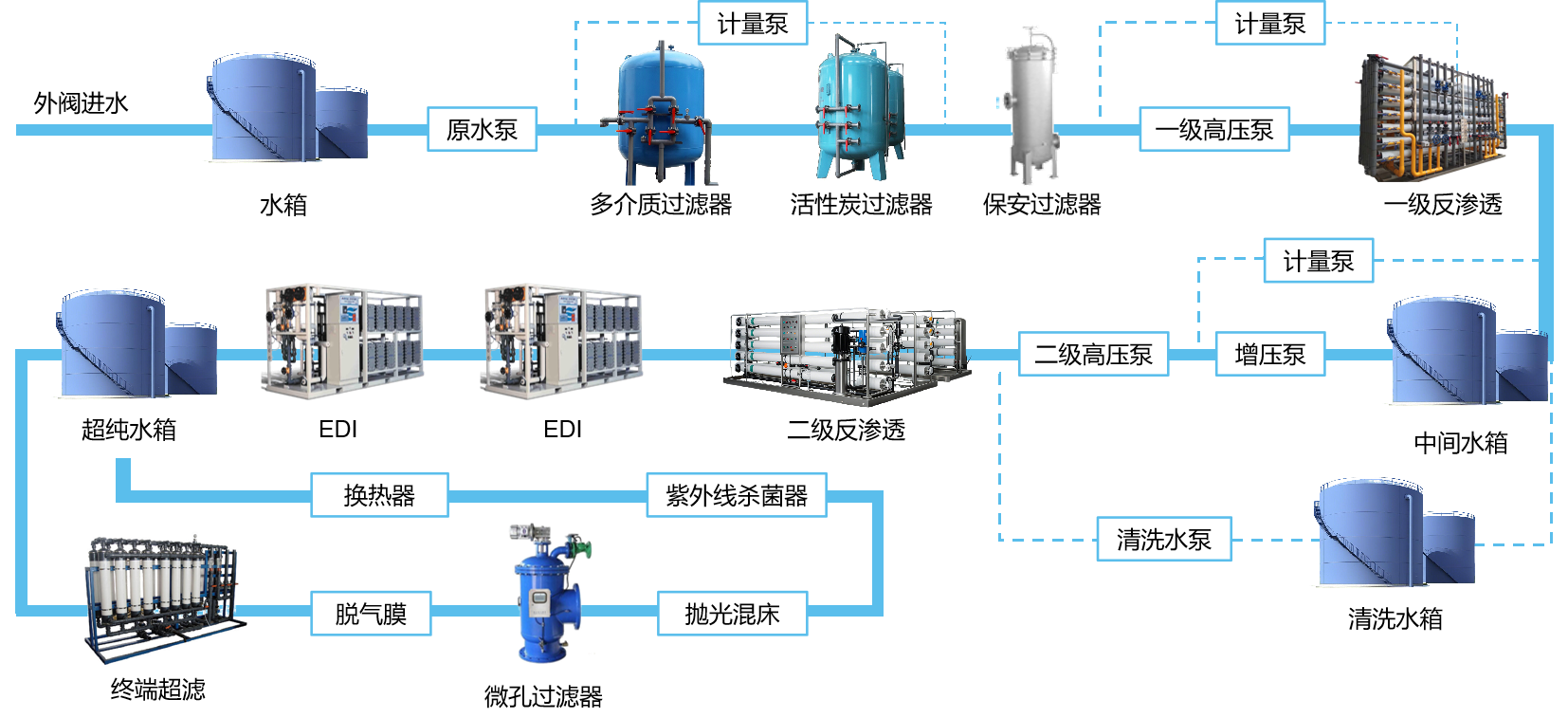

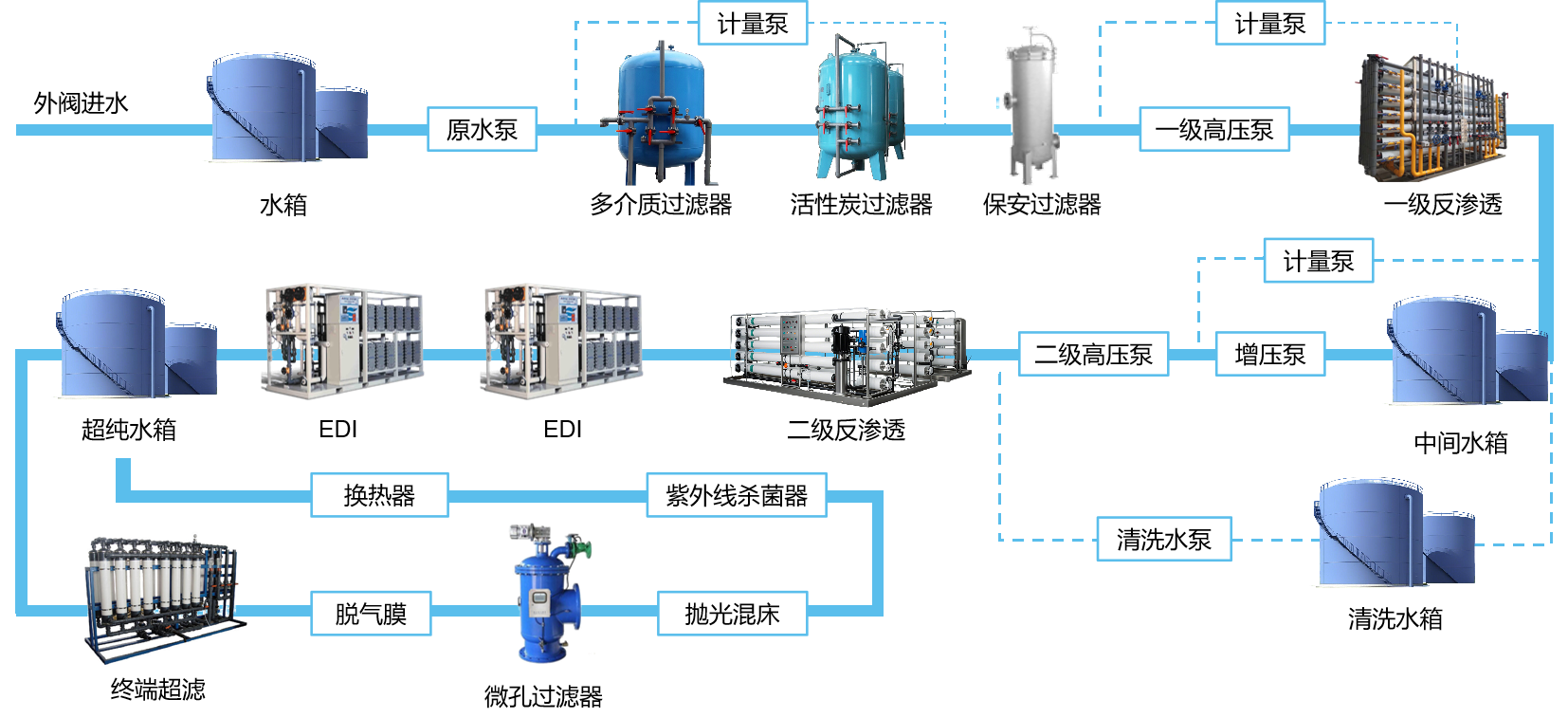

3、Flexible Process Adaptation Capability: Modular design enables rapid adjustment of pretreatment (e.g., ultrafiltration) and polishing processes (secondary EDI deep desalination) to adapt to complex water quality fluctuations.