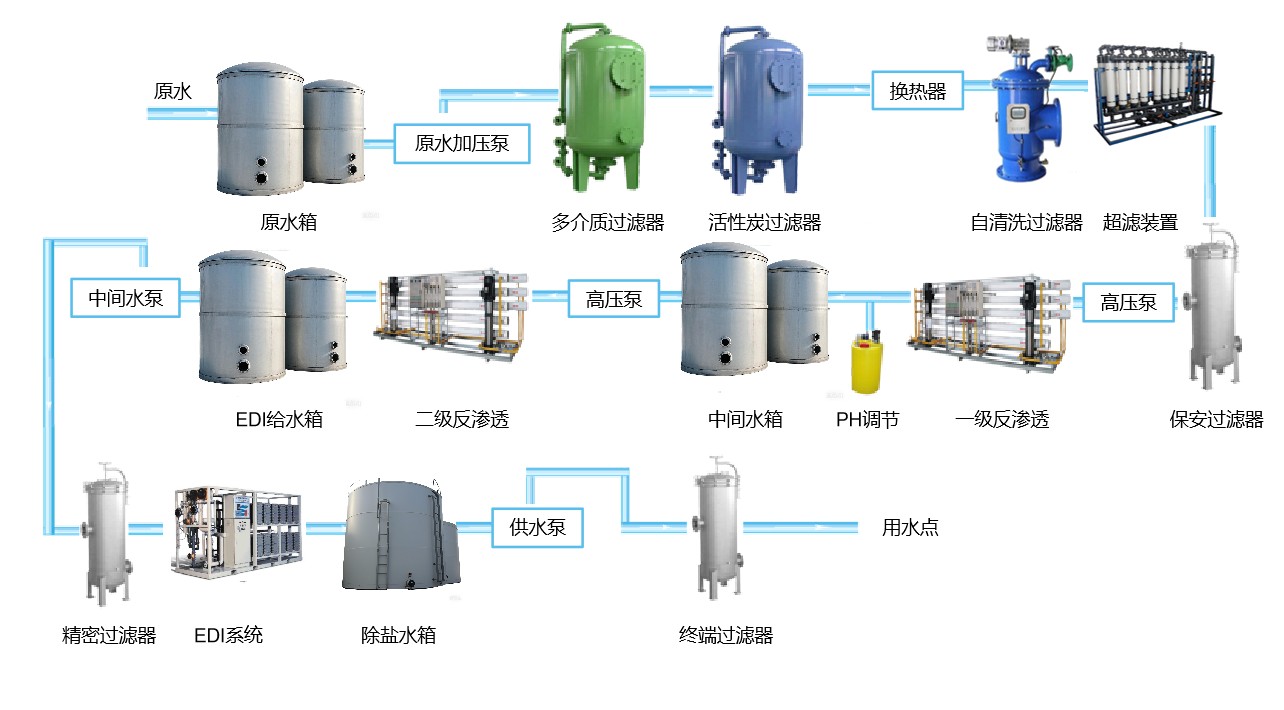

After pretreatment (coagulation, sedimentation, filtration), the raw water is driven by pressure to remove suspended solids, colloids, viruses and other impurities through microfiltration (MF) and ultrafiltration (UF). Reverse osmosis (RO) is used for pre-desalination, while electrodeionization (EDI) or ion exchange is applied for deep desalination, meeting the high-quality demineralized water requirements for boiler make-up water. This process features mature technology, stable operation, one-touch startup, and intelligent management. It serves industries such as power, coal chemical, petrochemical, metallurgy, electronics, and light industry.

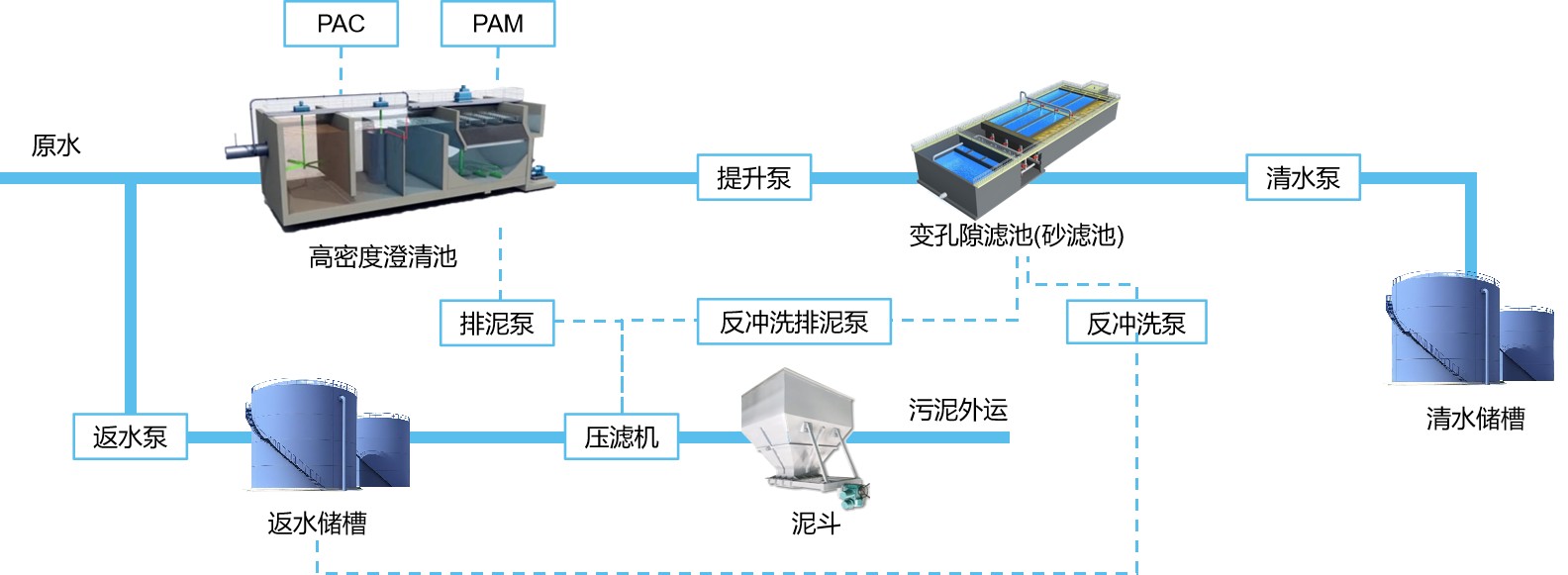

After advanced treatment, the effluent from municipal wastewater treatment plants is used as make-up water for circulating cooling systems and raw water for boiler make-up water.

Process Characteristics:

- Large water treatment capacity

- Stable effluent quality

- Low operation costs

- Capable of one-touch startup and unattended operation

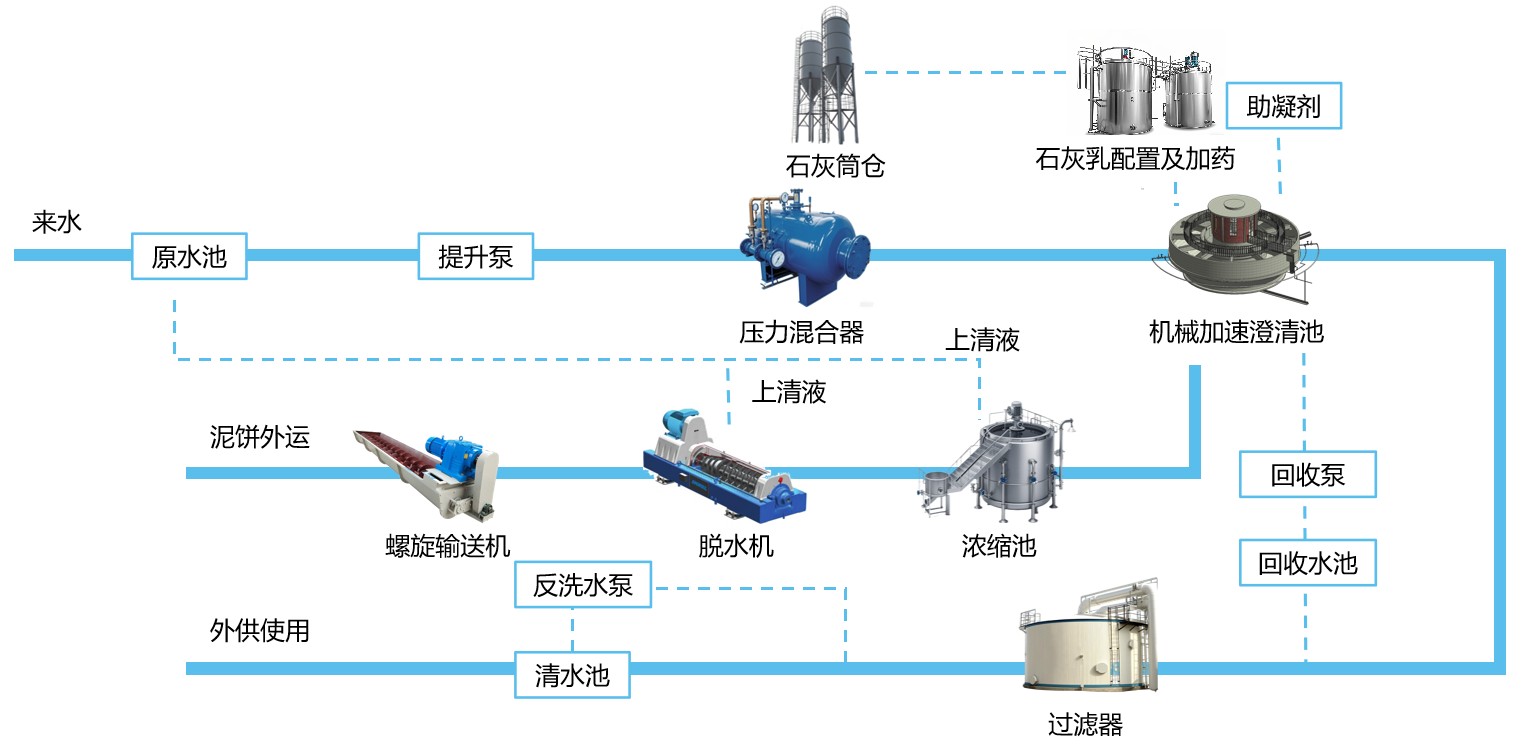

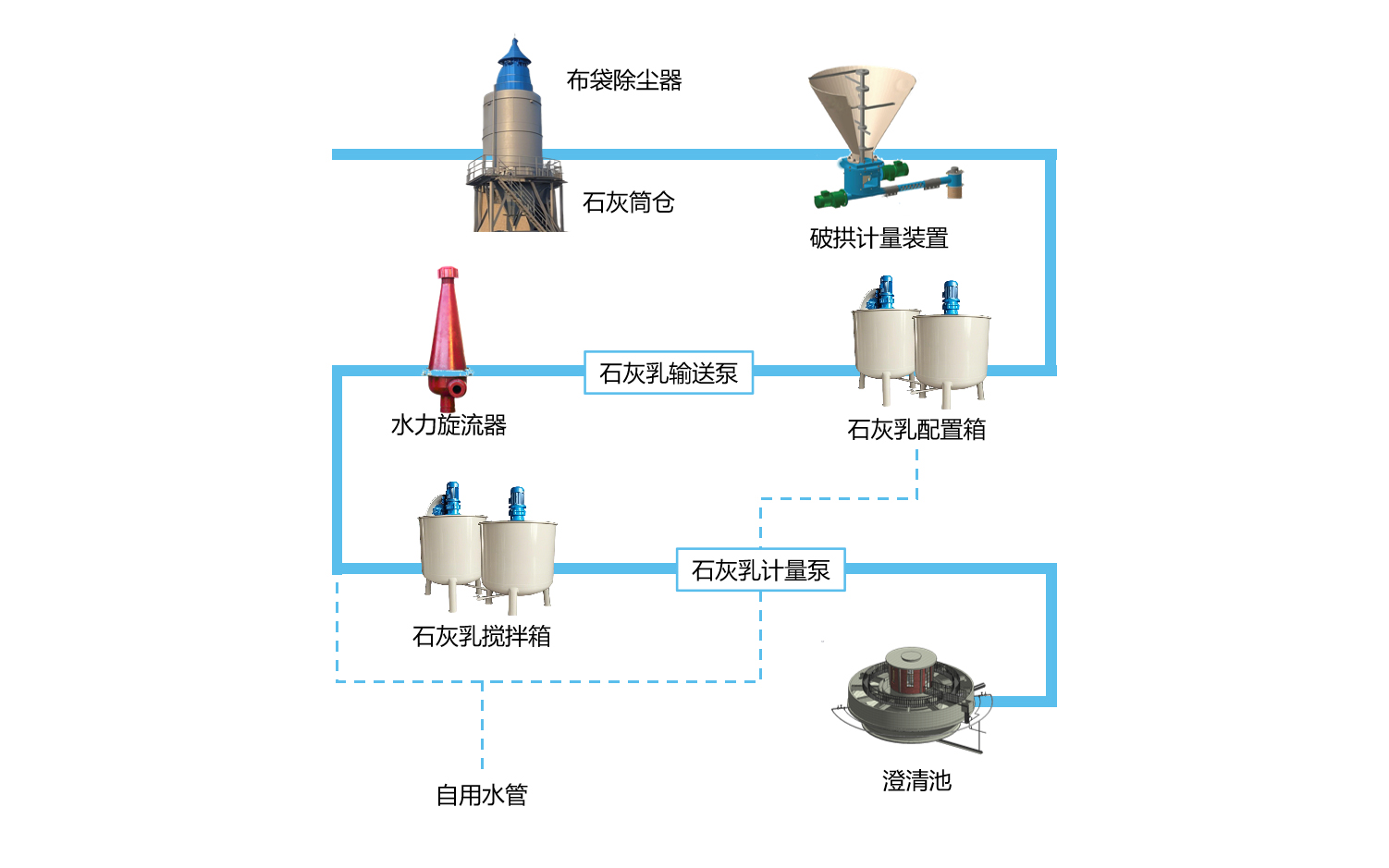

Hysunny's independently developed lime/soda ash metering and dosing system ensures a leak-proof environment for lime and soda ash, preventing blockages during material feeding and maintaining stable concentration. This provides a reliable guarantee for the stable operation of reclaimed water reuse systems and circulating cooling water treatment systems.

Application Areas:

Serving industries such as power, coal chemical, petrochemical, metallurgy, and light industry.

Raw water pretreatment, through the physicochemical synergistic effect of coagulation, sedimentation, and filtration, effectively reduces the content of suspended solids, colloids, and organic matter in water, ensuring the efficient and stable operation of subsequent membrane separation and desalination processes. Its modular design and intelligent control further enhance the system's flexibility and economic efficiency.

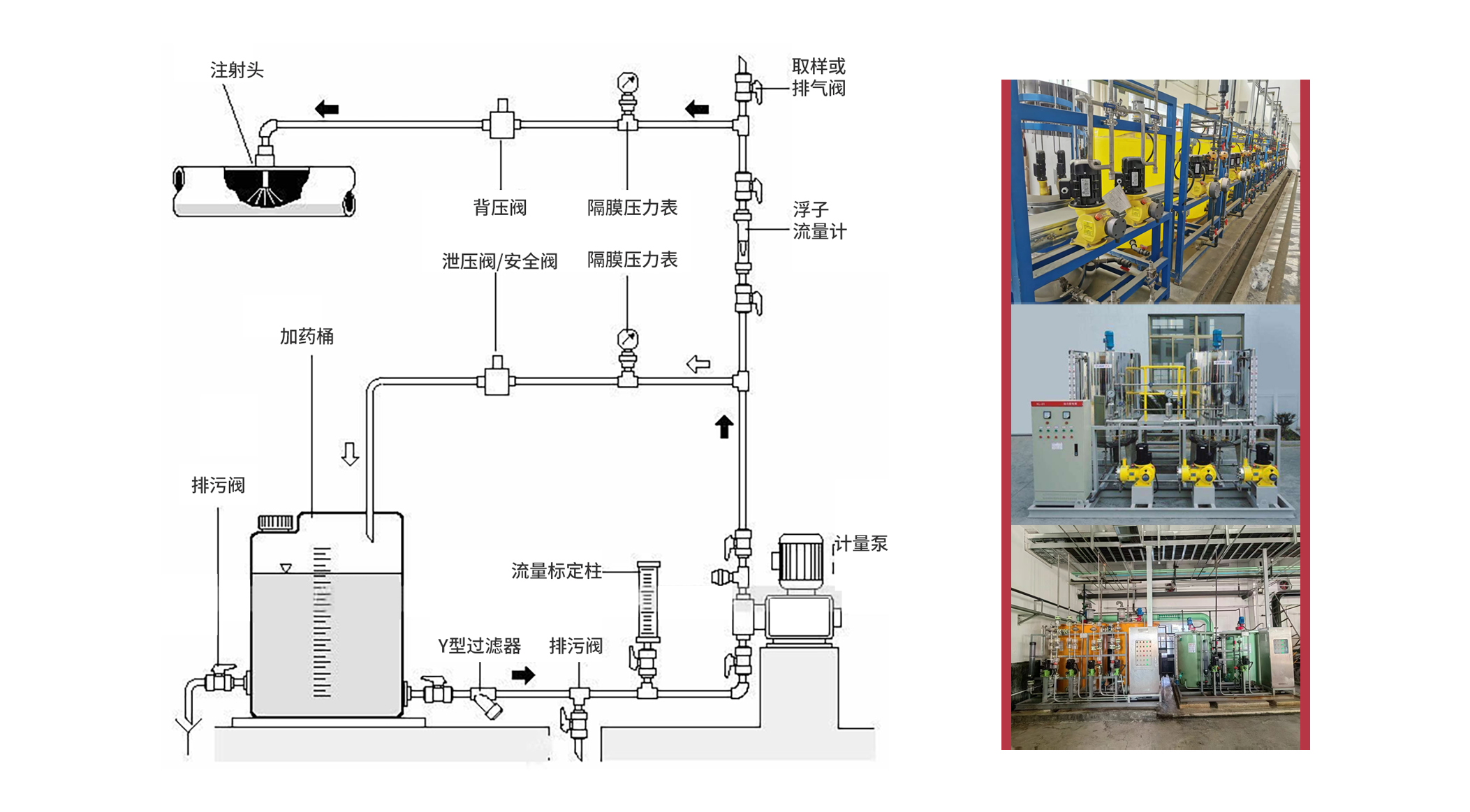

The preparation of lime milk adopts the volume metering method to ensure stable concentration of lime milk. The preparation, transportation, and metering of lime milk are controlled by automated program. The liquid level in the lime milk mixing tank is automatically maintained between high and low levels. A slide gate valve is built into the upper part of the slaked lime metering hopper to prevent dust from overflowing during lime feeding. This process can completely prevent dust from flying and lime milk from overflowing in the room. Even without a room bag filter, the workshop can remain dust-free, greatly improving indoor hygiene conditions. The system features integrated modular design, achieving precise dosing (error ≤1%), high-efficiency dust removal (≥99.5%), and 85% water saving. It is suitable for scenarios with large water quality fluctuations and reduces lime consumption by 18-22% compared to traditional processes.

1、Coagulant and coagulant aid dosing system

The coagulant uses powdered polymeric iron, and the coagulant aid uses polymeric polyacrylamide. Both are added at the pressure-type mixer before the clarifier. The chemicals are mixed evenly with the incoming water and then enter the clarifier. The chemical dosage is automatically regulated by PID according to the flow rate of the clarifier.

2. Chlorine dioxide dosing system

A compound chlorine dioxide generator is selected, and the addition point is set at the end of the pressure-type mixer at the filter outlet. Considering that microorganisms may breed during long-term shutdown of the filter, a shock chlorination point is set on the filter inlet header.

3. Concentrated sulfuric acid dosing system

When the suspended calcium carbonate in the clarifier effluent encounters sulfuric acid, it dissolves, resulting in the acid dosage being 0.2-0.3 mmol/L higher before the filter. The previous practice of setting the acid addition point upstream was mainly applied in variable porosity square filters to prevent agglomeration of filter media in subsequent filter systems. This filtration system uses a double-chamber filter, which has no filter media agglomeration issue, so the acid addition point is set after the filter. The acid dosage can be automatically regulated by PID according to the pH value at the pressure-type mixer outlet.utlet.