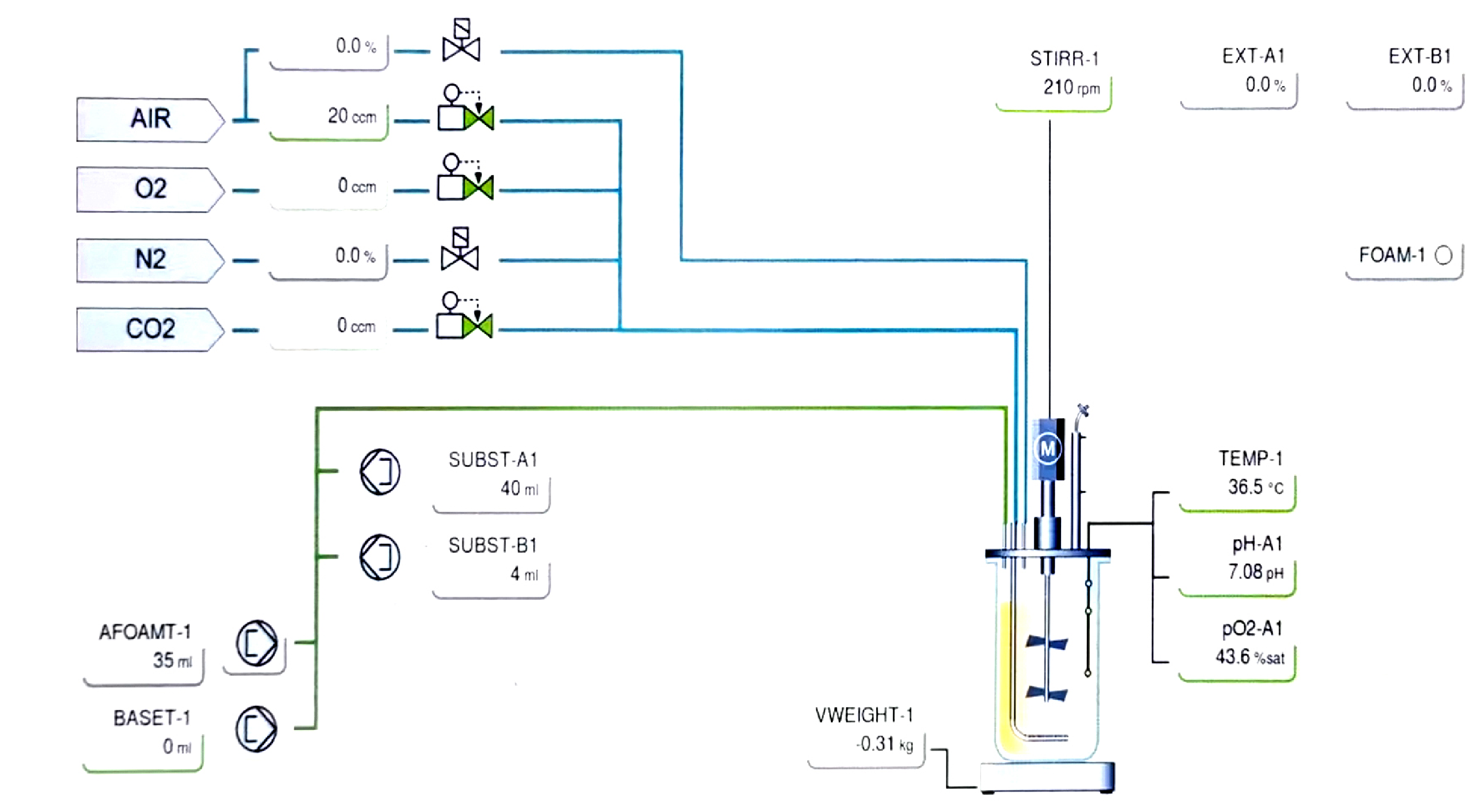

Process Flow Diagram

Technical Reserve

Integrated Process Analytical Technology (PAT) achieves sub-level precision control of critical parameters. Through a fully enclosed aseptic system and modular pre-installed platform, it simultaneously meets data integrity regulatory requirements, providing end-to-end technological empowerment for biopharmaceutical enterprises from cell culture to microbial fermentation.

1、Bioreactor Process:316L stainless steel tank with mirror-polished surface (Ra≤0.4μm), integrated with pH/DO/Temp three-parameter interlocking control.

2、PAT Technology:Real-time monitoring of dissolved oxygen (±0.1%), pH (±0.05), and temperature (±0.1℃), with fermentation success rate ≥99%.

3、Closed System Design: SIP (Steam-in-Place)/CIP (Clean-in-Place) sterilization reduces cross-contamination risk by 90%, compliant with FDA 21 CFR Part 11 electronic batch records.

4、Modular Design:3D simulation design + pre-fabricated workshop enables flexible combination of functional modules, effectively shortening on-site construction time.

Industrialization Advantages

Through an intelligent production platform, we integrate global high-end resources, leverage internationally certified processes and modular pre-integrated architecture, and combine a full-lifecycle technical service network to drive efficient and reliable delivery of bioprocessing equipment and close the loop on operation and maintenance.

1、Intelligent Production Platform:MES (Manufacturing Execution System) enables end-to-end digital management of the entire production process; modular design drastically reduces on-site construction time.

2、Global Supply Chain:Backed by a German DVS (Deutscher Verband für Schweißen) welding certification team and imported equipment to ensure high-precision welding processes.

3、Full-Lifecycle Services:24-hour response mechanism providing equipment maintenance, PLC program optimization, and compliance audit services.

Related products